Frame

and Chassis

24 HOUR TOW

SERVICE

412 - 793

- 8108

We

do trailers... |

We

do custom exhaust systems and repairs...

Call Al Anytime...

412 - 793

- 8108

We

do trailers too!

|

Arrow Automotive Inspection Service...

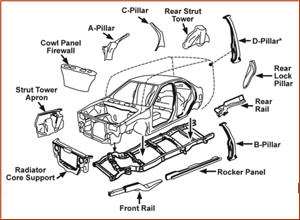

The Frame, Chassis and Uni-Body

Arrow Automotive Mechanics: Are

trained to inspect body sheet metal, frame and chassis or uni-body

construction during the state inspection

service. We look carefully for any possible cracks in frame, rusted

mounts, fuel delivery lines, brake lines, steering mounts, shock and

spring mounts. We also inspect potential rust damage under the uni-body

chassis, where welds can become weak and cause structural failure.

The The

uni-body

construction is unique because it requires the

chassis to be precision built around a non-frame based vehicle. This

construction may, over time become weak as welds are challenged by

daily vehicle use and harsh weather related driving.

It is important that uni-body vehicles remain road salt free

underneath the body. The salt can attack welds and over time,

destroy the support mains along the side body panels. This is

especially true when it comes to mini-vans and sport utility wagons.

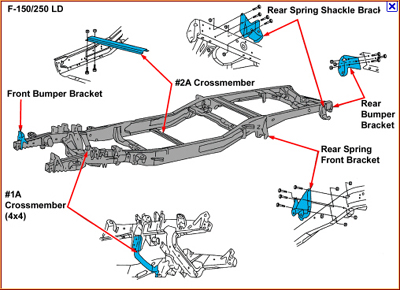

Body on Chassis

vehicles, such as utility wagons and light duty trucks are built

onto a frame. The CAB or CABIN is generally mounted to the chassis

with

large rubber mounts at all roll points. The FRAME is a complete

rolling chassis prior to body application. This creates a heavier

vehicle, but a more rigid vehicle. The frame inspection requires a

total investigation, however it remains as important if not more so

than uni-body designs. Most uni-body vehicles are front wheel

driven, while frame vehicles are driven at the rear. The image shows

points that our technicians inspect for rust or cracks. These points

are located at high stress areas along the chassis. On FWD vehicles,

the forward frame horns can crack and cause poor steering control.

These units can be repaired. The components shown in

"blue"

are readily available parts. with

large rubber mounts at all roll points. The FRAME is a complete

rolling chassis prior to body application. This creates a heavier

vehicle, but a more rigid vehicle. The frame inspection requires a

total investigation, however it remains as important if not more so

than uni-body designs. Most uni-body vehicles are front wheel

driven, while frame vehicles are driven at the rear. The image shows

points that our technicians inspect for rust or cracks. These points

are located at high stress areas along the chassis. On FWD vehicles,

the forward frame horns can crack and cause poor steering control.

These units can be repaired. The components shown in

"blue"

are readily available parts.

The

frame and chassis inspection includes: The

frame and chassis inspection includes:

REAR: A complete

inspection for rust, cracks or torn shock and spring

mounts.This includes all lines, hydraulic, brake and fuel. Gas tank

straps, spring

hangers, exhaust brackets and body cross members.

FRONT: We

inspect for all steering brackets, motor mounts, cross-members

and transmission mounts. Steering mounts, shock and spring seats. Upper

and lower

control arm mounting points.

On UNI-BODY vehicles we inspect for rear axle

hangers, shock and spring mounts. Gas tank mounts . All

fuel and brake lines are inspected. We look for excessive rust at

sub-frame points along the cabin.. Up

front we inspect the engine cradle. Most all axle components are mounted

to this assembly. We look for

cracked or worn engine mounts. We check all shock and strut towers for

rust and cracks.

Note that this complete look-over is also done during "steering and

suspension" inspection. This vehicle

review is done on all vehicles, auto, utility or light and medium trucks.

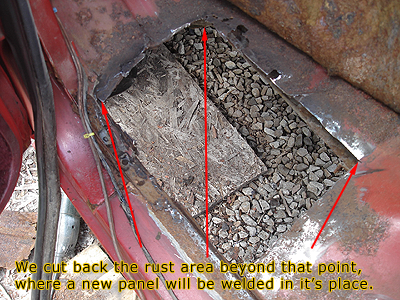

Rust is a bust !!!

All our technicians are trained to

inspect under-side body panels. Each vehicle has it's own unique

"rust foot print".

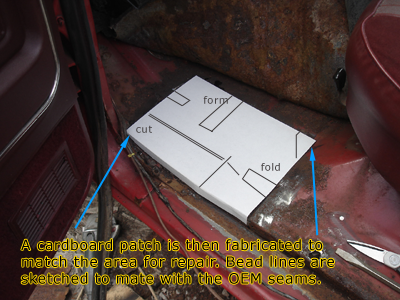

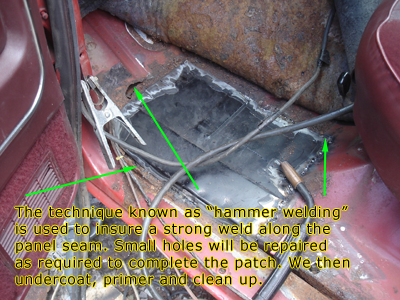

Al's Garage has a

local repair facility where, minor floor board and body side rust

repairs can be completed. These repairs are made using the same

material as original vehicle design. Floor panels may be replaced or

fabricated and bead rolled for strength. All panels are welded into

the floor using state-of-art welding practices. Body panels around

wheel wells, quarter panels, fenders and core supports can be

replaced or repaired. Damage levels from road salt and rust must

first be evaluated and estimated by our body technician. We then

estimate the over-all repair and offer you a solution that will fit

your budget.

Al's Garage has a

local repair facility where, minor floor board and body side rust

repairs can be completed. These repairs are made using the same

material as original vehicle design. Floor panels may be replaced or

fabricated and bead rolled for strength. All panels are welded into

the floor using state-of-art welding practices. Body panels around

wheel wells, quarter panels, fenders and core supports can be

replaced or repaired. Damage levels from road salt and rust must

first be evaluated and estimated by our body technician. We then

estimate the over-all repair and offer you a solution that will fit

your budget.

In

general we use the rule-of-thumb method. These repairs, as shown

here, would cost the owner-operator about $150.00. This floor board

repair on an F150 not only saved the owner money, it allowed him to

operate the vehicle for several years thereafter. This floorboard

repair was completed under safety inspection laws. Open floors must

not allow exhaust emissions to enter the cab or cabin area of a

vehicle. In

general we use the rule-of-thumb method. These repairs, as shown

here, would cost the owner-operator about $150.00. This floor board

repair on an F150 not only saved the owner money, it allowed him to

operate the vehicle for several years thereafter. This floorboard

repair was completed under safety inspection laws. Open floors must

not allow exhaust emissions to enter the cab or cabin area of a

vehicle.

Note: Patches using body putty or metal tapes will not pass state

inspection.

If you have any questions, please feel free

to contact us...You may bring your vehicle in for a total body,

and chassis inspection. Don't wait for the PA. Inspection cycle. Bring the unit in

at your convenience.

Call for an appointment today... |